1. Main application

1. Application of ribbed induction annealing production line;

2. Heating and burning through the hot upsetting production line of round steel bar and steel column;

3. Induction heating of square steel;

4. The diathermy of the whole iron rod;

5. Red forging of standard parts (nuts and bolts);

6. Partial through-fire forging forming of pipes;

7. Hot forging of cold-drawn solid section steel, hot upsetting of the tie head of cold-drawn seamless steel pipe;

8. Induction hot upsetting of drill pipe ends;

9. Heating forging of automobile maintenance tools (socket wrenches);

10. Heating, stamping and bending of high-voltage power transmission and power line tower angle steel plates;

11. On-line warm upsetting forging of copper bars;

12. The application of heating and warm upsetting in the hot upsetting production line of the automatic steel ball and steel column upsetting machine.

13. Hot forging of rivets, spring bars and road studs for railway accessories

14. Heating of supporting accessories such as circlips and U-shaped cables;

15. Heating ears of leaf springs, etc.

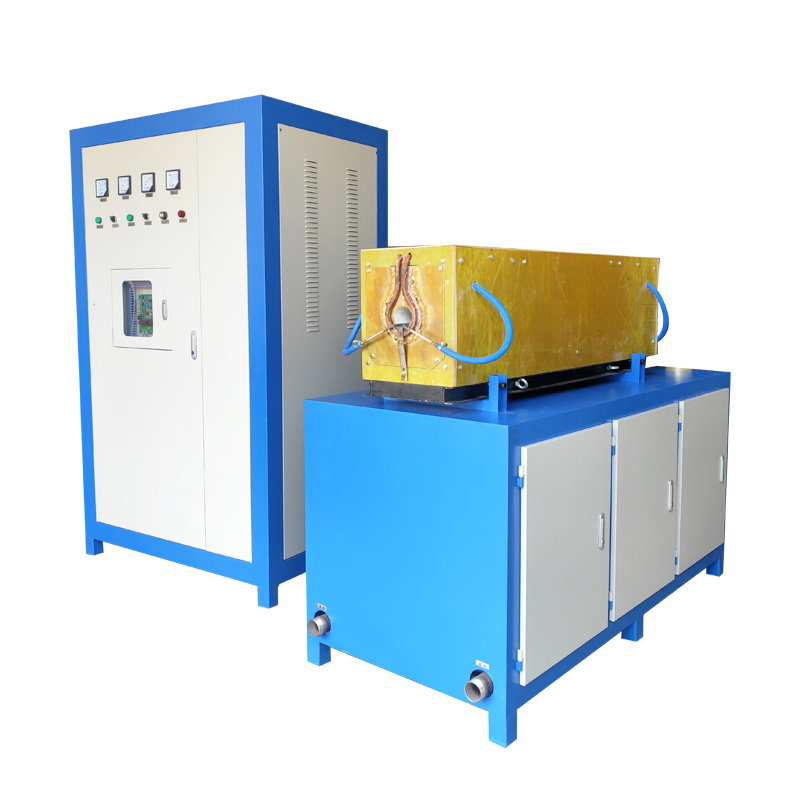

2. Main Features

1. Using IGBT power devices and our company's second-generation converter control technology, the equipment has higher reliability and lower maintenance costs;

2. Full load continuous rate, 24 hours operation;

3. With constant current/constant power control function, the heating efficiency is higher;

4. Full display of output power, frequency and current;

5. The installation is simple, only need to connect electricity and water to use, no need to install by special personnel;

3. Installation method

1. Place the main and auxiliary machines: Generally, the main machine (operation control machine) is placed on the top, and the auxiliary machine (power output machine) is placed at the bottom.

2. Connect the water and electricity of the main and auxiliary machines: Use the two thin water pipes in the accessories to connect the waterway in a straight up and straight down way. Then use the two cables in the accessories, red to red and black to black to connect the circuit. It must be tightened, and there should be no poor contact. Connect the ground wire of the main and auxiliary machines.

3. Power connection: This machine is a three-phase power supply mode (380V), and the three red wires are respectively connected to a special three-phase switch or air switch (above 65A). Reconnect the ground wire.

4. Water connection: The cooling water pressure used by this machine is 0.1Mpa-0.3Mpa. Please choose a 1.1KW water pump and a water tank or pool (the water pump should be selected according to the length of the distance, and the larger water pump should be selected for the long distance; the volume should be selected according to the continuous working time and workload, and a small cooling tower can be installed if necessary). The water outlet of the pump is connected to the water inlet of the machine with a water pipe, and the water outlet of the machine returns the return water to the pool with a water pipe to realize water circulation cooling.

5) Install the induction coil: According to the shape and size of the heated metal workpiece, select, install and fix the induction coil. Note that the induction coil cannot be short-circuited.

6. Putting the workpiece: Put the workpiece to be heated into the center of the induction coil, the surrounding gap should be basically the same, and the workpiece and the induction coil should not touch.

4. Operation steps

1. Water: Start the water pump and observe whether the water flow at the water outlet is normal.

2. Power on: first close the knife, then turn on the air switch at the back of the machine, and then turn on the power switch on the control board.

3. Setting: Select the operation mode (full automatic, semi-automatic, manual and foot control) according to your needs. When automatic and semi-automatic control, you need to set the heating time, holding time and cooling time (each time cannot be set to 0, otherwise it will not work properly). automatic cycle). Before using it for the first time and before you are proficient, you should use manual or foot control.

4. Start: Before each start, the heating power potentiometer should be adjusted to the minimum as much as possible, and then slowly adjust the temperature to the required power after starting. Press the start button to start the machine, at this time the heating indicator on the panel is on, and there will be a sound of normal work and the simultaneous flashing of the work light.

5. Observation and temperature measurement: During the heating process, visual inspection is mainly used to determine when to stop heating based on experience. Inexperienced operators can use a thermostat to detect the temperature of the workpiece.

6. Stop: When the temperature reaches the requirement, press the stop button to stop heating. You can start it again after replacing the workpiece.

7. Shutdown: The machine can work continuously for 24 hours. The power switch should be turned off when not in use, and the knife or the air switch at the rear of the machine should be turned off when not in use for a long time. When shutting down, the power should be cut off first and then the water should be cut off, so as to facilitate the heat dissipation inside the machine and the heat of the induction coil. Note: The machine should not work without load as much as possible, let alone run without load for a long time, otherwise, it will affect the performance and stability of the machine!

5. Maintenance

When used in places with poor air environment, dust should be prevented from entering the inside of the machine, and water must not be splashed into the machine. To keep the cooling water clean, change it regularly. High temperature environment should maintain air circulation.

6. Technical parameters

model | RAC-85KW |

Output Power | 120KW |

Input voltage | 380v 50hz |

Oscillation frequency | 10-30khz |

Pump Specifications | 2.2kw |

Cooling tower water flow | 15T/Hour |

pool | 2cube |

transformer | 50KW |

copper wire | 50square |

浙公網安備 33038102331513號

浙公網安備 33038102331513號